Frequently Asked Questions

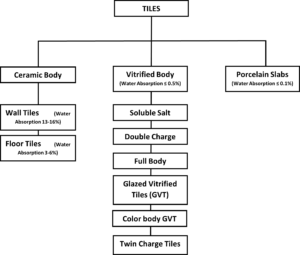

The process of converting something into a glass- like substance is known as Vitrification. This process can help convert a mixture of clay and raw materials into a uniform body and makes the internal bonding permanent. Firing the tile at a high temperature makes them impermeable to water. When you sink a piece of vitrified tile in water, it gains weight by 0.5%- which is the water absorption of the tile.

IMPORTANT: Outside India, Vitrified Tiles are only known as Porcelain Tiles.

Glazed Porcelain Tile will have a coating of glaze on the top of body. This layer is mainly of White Color which allows inject printing machine to print. Whichever design/ color you visualize, you can get a GVT/ PGVT suitable to it with the help of Digital Printing Technology. P in PGVT stands for Polished. They are shiny and offer wide variety of designs like marble and granite look. PGVT tiles are easy to clean and maintain, and can be used for any indoor application like hall, kitchen, living room, bathroom and bedroom. Surface options available with GVT – Polished, Matt, High- Gloss, Rustic, Carving, Sugar and Wood Texture.

Double charge means two layers are infused in tiles, It has different phase and body where the top layer design is the mixture of raw material infused with color pigment pressed to the base layer under high pressure. Upper layer of double charge tiles are 3 to 4mm thicker than other tiles.

Double Charge vitrified tiles is the first choice for heavy traffic, commercial and residential areas. They remain stable and shiny for years with low maintenance that makes them the perfect option to go for flooring at home, malls, cafeteria, hospitals, libraries, airports, villas and other interior as well as exterior areas. Surface options – Polished.

This type of tile used the same material from top to bottom. There is no glaze used. Sometimes they use transparent glaze- to seal the surface pores and make it ink resistant. Full Body Tiles can be used for steps, window sill and room border.

These tiles are Glazed Vitrified Tiles with matching body color. Color body tiles give the design possibility of a GVT tile and a matching body advantage of a full- body tile.

Porcelain Tiles/ Vitrified Tiles are better due to the following properties-

- Low water Absorption Rate < 0.5%

- Superior Durability

- High Stain Resistance

- Typical use in Indoor and Outdoor Wall and Floor

Ceramic Wall Tiles have the highest water absorption, approximately 13-16%. We offer artistic wall tiles where each design is a light/ dark version with a matching decorative punch (highlighter). Some designs also include coordinated border pieces. Ceramic Wall Tiles are not made to withstand high wear and tear but their light weight is a bonus for vertical installation and also easier to cut. Such tiles are set together, with thin grout lines. They can be mix and matched to create endless contrasts and custom- look patterns. Ceramic Wall Tiles are non- vitreous. A glazed layer on it will only make the surface – water and stain- resistant. If you are using adhesives, always ask for tiles with waterproof engobe.

Surface Finishes- Glossy, Matte, Rustic, Satin, Metallic

Thickness- 6 mm to 9 mm

For areas like showers, floors and exteriors in freezing climates- CHOOSE Vitrified Tiles.

When it comes to prices of different types of tiles it varies and depends on the below criteria…

Type – is it ceramic or porcelain?

Sub-type – wall, floor, soluble salt, double charge, GVT, color-body, full-body, etc

Size – bigger the size more premium the companies charge. But it is not always the case. E.g. subway wall tiles such as 100x200mm, 200x200mm, 100x300mm, etc… costs more compared to 300×450 mm, 300×600 mm

Surface finish – sugar finish, hi-gloss tile, carving effect, metallic effect, roto effect, etc have extra pricing

Brand – tile companies with better brand equity have higher the price

Yes it is possible to drill a hole through porcelain tiles, we need to keep few point in mind which are:-

- A special tool named Diamond drill is available in the market which is specially designed for drilling the porcelain tiles.

- It is also recommended that the tile is fixed correctly.

Daily Maintenance of Porcelain tiles (Vitrified tiles) are very easy following is the steps:-

- > 90 % of stain can be clean by simply wipe the glazed tiles with a soft sponge mop or with warm water- soap solution.

- In case stains are not removed by water soap-solution (Detergent) then we can use diluted hydrochloric acid

- Impervious (least absorbent)

- Vitreous

- Semi-vitreous

- Non-vitreous / Porous (most absorbent).

Unlike China, the grades of quality have different names as under

Premium = 1st choice

Standard = 2nd choice

Commercial = 3rd choice